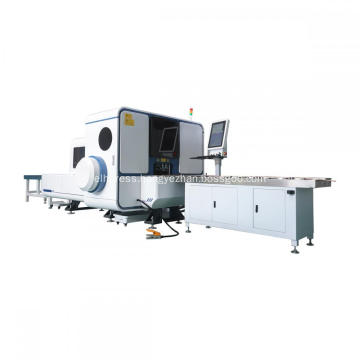

New Fast CNC Busbar Punching And Shearing Machine

- Packaging:

- Seaworthy packing

- Productivity:

- 20Sets/Month

- Brand:

- Euro-Asia

- Transportation:

- Ocean

- Place of Origin:

- Shandong, China

- Supply Ability:

- 200Sets/Year

- Certificate:

- ISO

- Port:

- Qingdao

Basic Info

Model No.: EMAC-BP

Product Description

1. CNC Busbar Punching And Shearing Machine GJ3D software--This is our independent patent in busbar processing, which can realize 3D automatic programming and dynamic simulation.

2. Double clamps of CNC busbar punching and shearing machine--Comparing other single clamp, double clamps can make processing more accurate and stable.

3. Hydraulic system of CNC busbar punching and shearing machine-- Piston pump (rather than gear pump) has large drive power and realize high efficiency.

4. Main components of CNC busbar punching and shearing machine--Imported, so the quality and service life can be guaranteed.

Main techincal parameters

Control Section Serial No. Name Instruction 1 Programmable Control OMRON/Schneider 2 Sensor Schneider 3 Control Button OMRON 4 Touch Screen OMRON 5 Computer Lenovo 6 AC Contactors ABB 7 Circuit Breaker ABB 8 Servo Motors YASKAWA(Japan) or Schneider 9 Servo Drivers YASKAWA(Japan) or Schneider 10 Control software and Three-dimensional Busbar Processing System(GJ3D) computer-aided design Transmission System Serial No. Name Illustration 1 Precision Linear Guide Rail Taiwan HIWIN 2 Precision Ball Screw Cylinder Taiwan HIWIN 3 Bearing Japan NSK Hydraulic Section Serial No. Name Illustration 1 High Pressure Electromagnetic valve Italy 2 High Pressure Tube Germany Rivaflex 3 High Pressure Oil Piston Pump Rexroth

| Technical parameter | |||

| Description | Unit | Parameter | |

| Press Force | Punching Unit | kN | 500 |

| Shearing Unit | kN | 500 | |

| Embossing Unit | kN | 500 | |

| X Max Speed | m/min | 60 | |

| X Max Stroke | mm | 2000 | |

| Y Max Stroke | mm | 530 | |

| Z Max Stroke | mm | 350 | |

| Stroke of Hit Cylinder | mm | 45 | |

| Max hit speed | HPM | □120 □150 | |

| Tool | Punching Mould | set | □6 □8 |

| Shearing Mould | set | □1 □2 | |

| Embossing Mould | set | □1 | |

| Control Axis |

| □3 □5 | |

| Hole Pitch Accuracy | mm/m | ±0.20 | |

| Max hole punch size | mm | Φ32( Thickness of Copper bar <12mm) | |

| Max embossing area | mm² | 160×60 | |

| Max Allowable sheet dimension(L*W*H) | mm | 6000×200×15 | |

| Total power | kw | 14 | |

| main machine dimension:L*W | mm | 7500X2980 | |

| Total weight | kg | 7600 | |

Packing details:

Exhibition show

Product Categories : Busbar Punching Machine