Cable Connectors I/O Connectors

- Transportation:

- Ocean,Land,Express,Air,Others

- Supply Ability:

- 100000PCS

- Port:

- SZ

Basic Info

Model No.: Cable Connectors I/O Connectors

Product Description

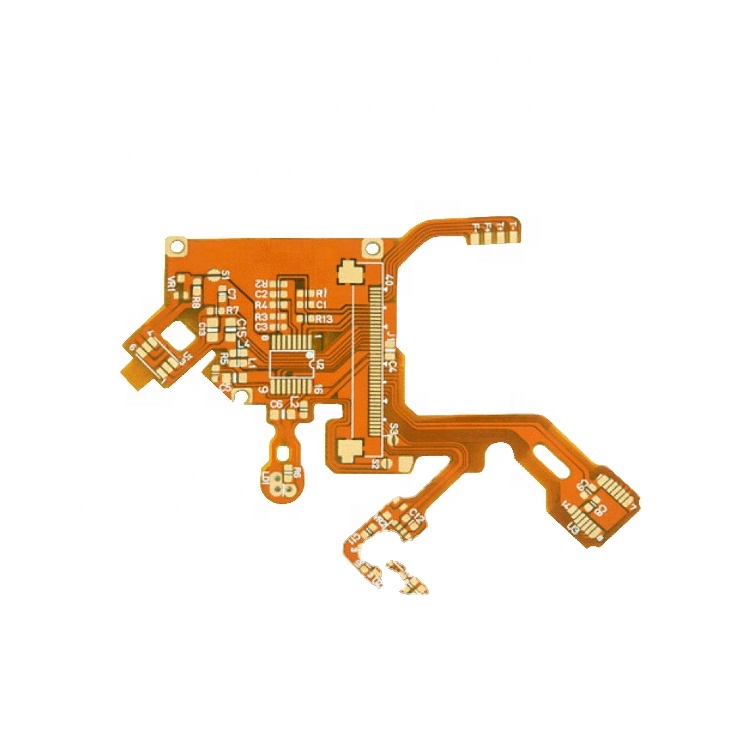

What is a flexible printed circuit board?

Flexible printed circuit (Flexible Printed Circuit, FPC), also known as flexible circuit board, flexible circuit board, which is light in weight, thin in thickness, free to bend and fold, and the excellent characteristics of rigid PCB combined into rigid-flex board It is very popular, but domestic FPC quality inspection mainly relies on manual visual inspection. Quick Turn PCB has high cost and low efficiency. With the rapid development of the electronics industry, the design of circuit boards is becoming more and more high-precision and high-density. Traditional manual inspection methods can no longer meet the production needs. FPC defect automatic detection has become an inevitable trend in the development of the industry. Flexible circuit (FPC) is a technology developed by the United States for the development of space rocket technology in the 1970s. It is made of polyester film or polyimide as a substrate with high reliability and excellent flexibility. By embedding a circuit design on a flexible thin and light plastic sheet, a large number of precision components can be stacked in a narrow and limited space to form a flexible PCBA. This kind of circuit can be bent at will, folded, light weight, small size, good heat dissipation, and convenient PCB assembly, breaking through the traditional interconnection technology. In the structure of the flexible circuit, the materials are insulating film, conductor and adhesive.

1. Insulating film

Flexible circuit board

Flexible circuit board

The insulating film forms the base layer of the circuit, and the adhesive bonds the copper foil to the insulating layer. In a multi-layer design, it is then bonded to the inner layer. They are also used as a protective cover to insulate the circuit from dust and moisture and to reduce stress during flexing. The copper foil forms a conductive layer.

In some flexible circuits, rigid components made of aluminum or stainless steel are used, which can provide dimensional stability, physical support for the placement of components and wires, and stress relief. The adhesive bonds the rigid component and the flexible circuit together. Another material is sometimes used in flexible circuits. It is an adhesive layer, which is formed by coating adhesive on both sides of an insulating film. The adhesive layer sheet provides environmental protection and electrical insulation functions, and can eliminate a layer of film, and has the ability to bond multiple layers with a small number of layers.

There are many types of insulating film materials, but the most commonly used are polyimide and polyester materials. Nearly 80% of all flexible circuit manufacturers in the United States use polyimide film materials, and about 20% use polyester film materials. Polyimide materials are non-flammable, geometrically stable, have high tear strength, and have the ability to withstand welding temperatures. Polyester, also known as polyethylene terephthalate (Polyethyleneterephthalate for short: PET) ), its physical properties are similar to polyimide, it has a lower dielectric constant and absorbs little moisture, but it is not resistant to high temperatures. Polyesters have a melting point of 250°C and a glass transition temperature (Tg) of 80°C, which limits their use in applications that require a lot of end welding. In low temperature applications, they exhibit rigidity. Nevertheless, they are suitable for use in products such as phones and other products that do not need to be exposed to harsh environments. Polyimide insulating films are usually combined with polyimide or acrylic adhesives, and polyester insulating materials are generally combined with polyester adhesives. The advantages of combining with materials with the same characteristics, after dry welding, or after multiple lamination cycles, can have dimensional stability. Other important characteristics in adhesives are low dielectric constant, high insulation resistance, high glass transition temperature and low moisture absorption.

2. Conductor

Copper foil is suitable for use in flexible circuits. It can be electrodeposited (Electrodeposited for short: ED) or plated. One side of the electrodeposited copper foil has a glossy surface, while the processed surface on the other side is dull and dull. It is a flexible material that can be made into many thicknesses and widths. The matte side of ED copper foil is often specially treated to improve its bonding ability. In addition to flexibility, forged copper foil also has the characteristics of rigidity and smoothness. It is suitable for applications that require dynamic deflection.

3. Adhesive

In addition to bonding the insulating film to the conductive material, the adhesive can also be used as a covering layer, as a protective coating, and as a covering coating. The main difference between the two lies in the application method used. The cover layer is bonded to the cover insulating film to form a circuit with a laminated structure. The screen printing technology used for covering and coating the adhesive. Not all laminate structures contain adhesives, and laminates without adhesives form thinner circuits and greater flexibility. Compared with the laminated structure based on adhesive, it has better thermal conductivity. Due to the thin structure of the adhesive-free flexible circuit and the elimination of the thermal resistance of the adhesive, thereby improving the thermal conductivity, it can be used in a working environment where the flexible circuit based on the adhesive laminated structure cannot be used. .

Prenatal treatmentedit

In the production process, in order to prevent excessive opening and short circuits from causing too low yield or reducing the problem of FPC board scrap and replenishment caused by rough process problems such as drilling, rolling, and cutting, and to evaluate how to select materials to achieve customer use For the best effect of flexible circuit boards, pre-production pretreatment is particularly important.

Pre-natal pretreatment, there are three aspects that need to be dealt with, and all three aspects are completed by engineers. The first is the FPC board engineering evaluation, which is mainly to evaluate whether the customer's FPC board can be produced, whether the company's production capacity can meet the customer's board-making requirements and unit cost; if the engineering evaluation is passed, the next step is to prepare materials immediately to meet each production link Finally, the engineer processes the customer’s CAD structure drawing, gerber line data and other engineering documents to suit the production environment and production specifications of the production equipment, and then delegates the production drawings and MI (engineering process card) to the The production department, document control, purchasing and other departments enter the regular production process.

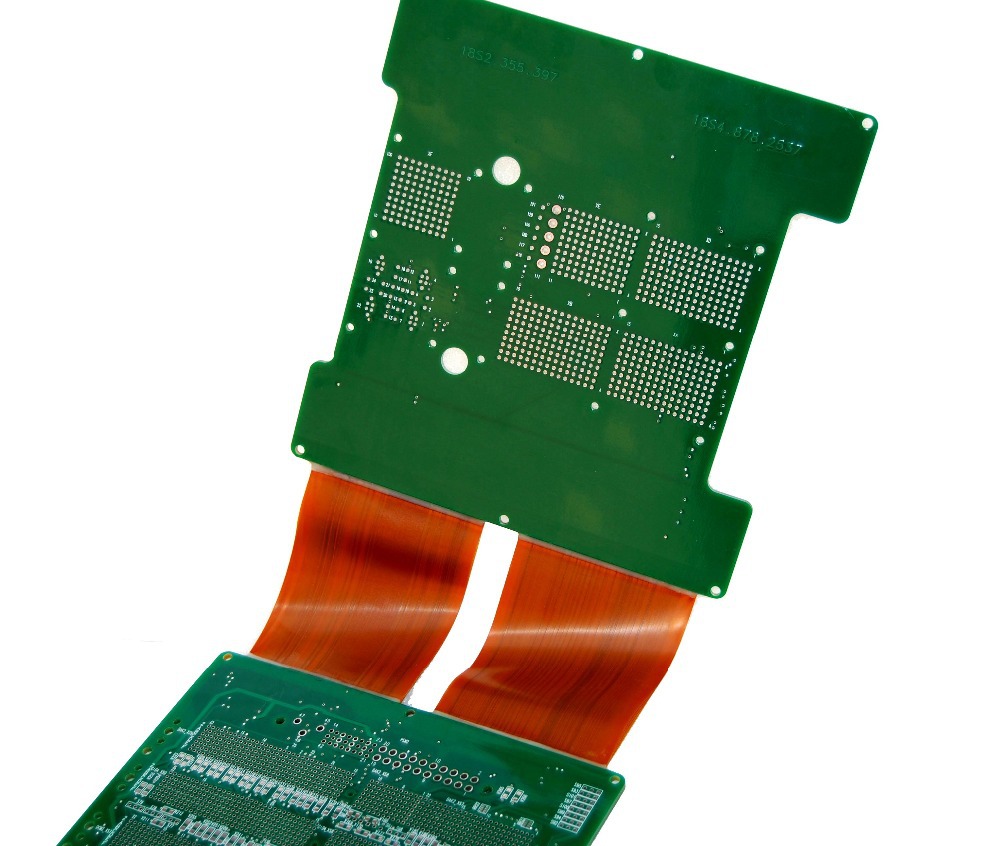

Double panel system

Cutting → Drilling → PTH → Electroplating → Pre-treatment → Dry Film Pasting → Alignment → Exposure → Development → Graphic Plating → Stripping → Pretreatment → Dry Film Pasting → Alignment Exposure → Development → Etching → Stripping → Surface Treatment → Paste the cover film → Pressing → Curing → Immersion of nickel gold → Printing characters → Shearing → Electrical test → Punching → Final inspection → Packaging → Shipment

Single panel system

Cutting → Drilling → Pasting Dry Film → Aligning → Exposure → Developing → Etching → Stripping → Surface Treatment → Covering Film → Pressing → Curing → Surface Treatment → Immersion Nickel Gold → Printing Characters → Cutting → Electrical Measurement → Punching Cutting → final inspection → packaging → shipment

Feature editing Voice

1. Short: PCB assembly work hours are short

All lines are configured, eliminating the need to connect redundant cables

2. Small: smaller than PCB

Can effectively reduce the product volume and increase the convenience of carrying

3. Light: lighter than PCB (hard board)

Can reduce the weight of the final product

4. Thin: thickness is thinner than PCB

Can improve flexibility. Strengthen the assembly of three-dimensional space in a limited space

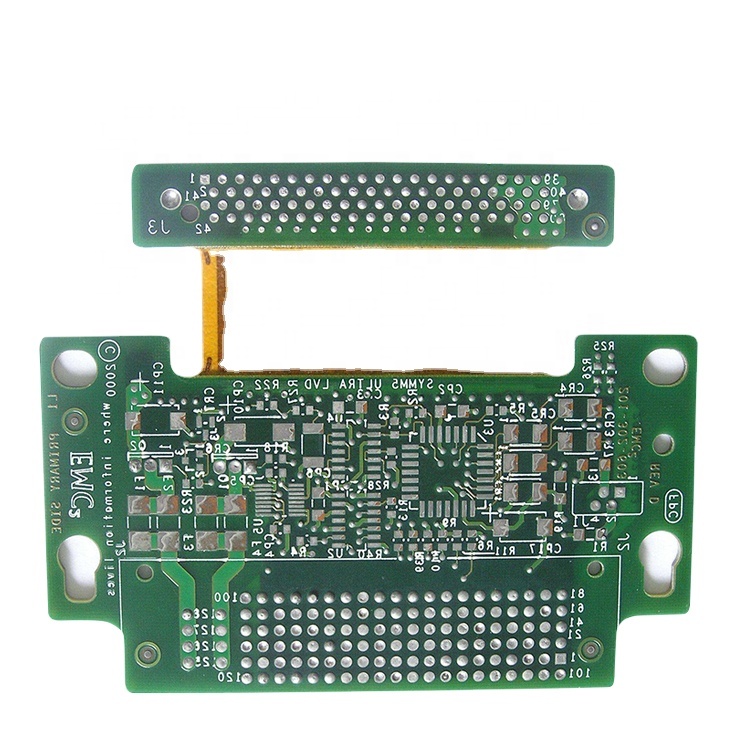

Basic structure editing Voice

Flexible circuit board

Flexible circuit board

Copper Film

Copper foil: basically divided into electrolytic copper and rolled copper. The common thickness is 1oz 1/2oz and 1/3 oz

Substrate film: There are two common thicknesses: 1mil and 1/2mil.

Glue (adhesive): The thickness is determined according to customer requirements.

Cover Film

Cover film protection film: for surface insulation. Common thicknesses are 1mil and 1/2mil.

Glue (adhesive): The thickness is determined according to customer requirements.

Release paper: avoid the adhesive sticking to foreign matter before pressing; easy to work.

Stiffener Film (PI Stiffener Film)

Reinforcement board: Reinforce the mechanical strength of FPC, which is convenient for surface mounting operations. The common thickness is 3mil to 9mil.

Glue (adhesive): The thickness is determined according to customer requirements.

Release paper: avoid the adhesive sticking to foreign matter before pressing.

EMI: Electromagnetic shielding film to protect the circuit inside the circuit board from outside interference (strong electromagnetic area or susceptible to interference area).

Pros and consedit:

The advantages of multi-layer circuit boards: high assembly density, small size, light weight, because of high-density assembly, the connection between components (including parts) is reduced, thereby increasing reliability; it can increase the wiring layer, and then increase the design flexibility; The impedance of the circuit can also be formed, and a certain high-speed transmission circuit can be formed. The circuit and electromagnetic shielding layer can be set, and the metal core layer can also be installed to meet the functions and requirements of special thermal insulation. It is easy to install and has high reliability.

Disadvantages of multi-layer pcb boards (unqualified): high cost, long cycle; high reliability inspection methods are required. Multilayer printed circuit is the product of electronic technology, multi-function, high speed, small volume and large capacity. With the development of electronic technology, especially the wide application of large-scale and ultra-large-scale integrated circuits, the rapid, high-precision, high-number change directions of the multilayer printed circuit with higher density appear fine lines.

FPC will continue to innovate from four aspects in the future, mainly in:

1. Thickness. The thickness of FPC must be more flexible and must be thinner;

2. Folding resistance. The ability to bend is an inherent characteristic of FPC. In the future, FPC must be more resistant to bending, which must exceed 10,000 times. Of course, this requires a better substrate;

3. Price. At this stage, the price of FPC is much higher than that of PCB. If the price of FPC comes down, the market will definitely be much broader.

4. Technological level. In order to meet various requirements, the FPC process must be upgraded, and the minimum aperture and minimum line width/line spacing must meet higher requirements.

Product Categories : Components Sourcing > Cable Connectors I/O Connectors