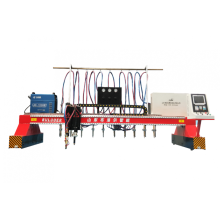

XBJ-6 Metal Sheet Edge Milling Machine Chamfering Machine

- Productivity:

- 50 Sets/Month

- Place of Origin:

- China

- Supply Ability:

- 50 Sets/Month

- Certificate:

- GS, SGS, CE, ISO 9001

Basic Info

Model No.: XBJ-6

Product Description

Model NO.: XBJ-6 Structure: Flat Milling Cutter Structure: Indexable Type Automatic Grade: Automatic Certification: GS, SGS, CE, ISO 9001 angle of milling: 45 DEGREE Trademark: HYMT Origin: China Object: Sheet Milling Cutter Type: Angle Milling Cutter Controlling Mode: Program Control Precision: High Precision Condition: New THICKNESS: 6-50mm Specification: max milling length: 6000mm HS Code: 84688000 Main functions:

Compared with the traditional edge milling machines, this series machines is dismountable in their tracks, more rational in structure by heat-treatment of the bench, more reliable and stable in the milling and turning head's running. The feed and feed-back systems are fully independent respectively. The angle of the milling tool's tray is convenient in adjustment, and the custom-built tool rest and the normal tool rest can be inter-converted. They are the updated products of the traditional edge Milling Machine

Main specifications:.

HYMT Machinery services:

1.Standardization of Service "212"

2: response in 2 hours

1: provide solution in 1 day

2: solve complaint in 2 days

2.Installation Service

Installation Services are available with all HYMT machines. We dispatch technician to customer's

factory for installation and preoperation of machines.

3.Training Service

Our technician is available to your factory and offer training of how to use our machines. As well, you

may send your technician to our company to learn how to operate machines.

4.Quality Guarantee

We guarantee the quality of machine (e.g. processing speed and working performance is the same as

the data of samples making). We sign the agreement with detailed technical data.

We arrange final test before shipment. We run the machine for a few days, and then use customer's

materials for test. After making sure machine is the best performance, then make shipments. Contact us if you need more details on machinery. We are ready to answer your questions on packaging, logistics, certification or any other aspects about machine tool、machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

Compared with the traditional edge milling machines, this series machines is dismountable in their tracks, more rational in structure by heat-treatment of the bench, more reliable and stable in the milling and turning head's running. The feed and feed-back systems are fully independent respectively. The angle of the milling tool's tray is convenient in adjustment, and the custom-built tool rest and the normal tool rest can be inter-converted. They are the updated products of the traditional edge Milling Machine

Main specifications:.

| Model | XBJ-6 | XBJ-9 | XBJ-12 |

| The angle of milling | 0-45 degree | ||

| The thickness of being processed steel plate | 6-50mm | ||

| The max depth of milling bevel edge at one time | 12mm | ||

| The traveling speed of crosswise milling | 0.3/0.5m.min | ||

| Back stroke milling speed | 5m/min | ||

| The rev. speed of milling spindle | 125-800m/min | ||

| The working pressure of hydraulic system | 3.5 | ||

| The number of cylinders | 8 pcs | 11 pcs | 15pcs |

| The height between platform and ground | 900mm | ||

| The power of driving motor | 1.1/0.85KW | ||

| The power of milling motor | 3KW | ||

| The power of pump motor | 5.5KW | 5.5KW | 5.5KW |

| Overall dimensions | 772x260x205cm | 1072x260x220cm | 1372x260x230cm |

HYMT Machinery services:

1.Standardization of Service "212"

2: response in 2 hours

1: provide solution in 1 day

2: solve complaint in 2 days

2.Installation Service

Installation Services are available with all HYMT machines. We dispatch technician to customer's

factory for installation and preoperation of machines.

3.Training Service

Our technician is available to your factory and offer training of how to use our machines. As well, you

may send your technician to our company to learn how to operate machines.

4.Quality Guarantee

We guarantee the quality of machine (e.g. processing speed and working performance is the same as

the data of samples making). We sign the agreement with detailed technical data.

We arrange final test before shipment. We run the machine for a few days, and then use customer's

materials for test. After making sure machine is the best performance, then make shipments. Contact us if you need more details on machinery. We are ready to answer your questions on packaging, logistics, certification or any other aspects about machine tool、machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

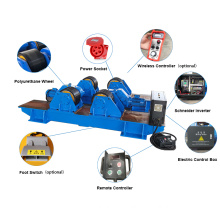

Product Categories : Welding Auxiliary Equipment

Premium Related Products

Other Products

Hot Products

JB23 die cutting press metalsmall press/die for power pressmetal cutting machine/plasma cutting machineq11-6x2000 cheap cnc plasma cutting machinehydraulic metal shear qc11y-20*3200/amada shearing machineqc12y-10*6000 imported tools metal machinesmini cnc qc12k-12*4000/cutter/automatic metal cutting machineautomatic stirrup bending machine XD-3512press brake 400 tons mechnical platecondenser bending machine WC67K-500T/6000YR27 hydraulic cotton bale press machinelaboratory hydraulic press/hydraulic tile presstitanium sheet hydraulic press/5000 ton hydraulic presshigh quality power hydraulic press/small 300 ton hydraulic press price100T C-frame type hydraulic press2-WC67Y/K the linkage of two hydraulic sheet metal bending machine